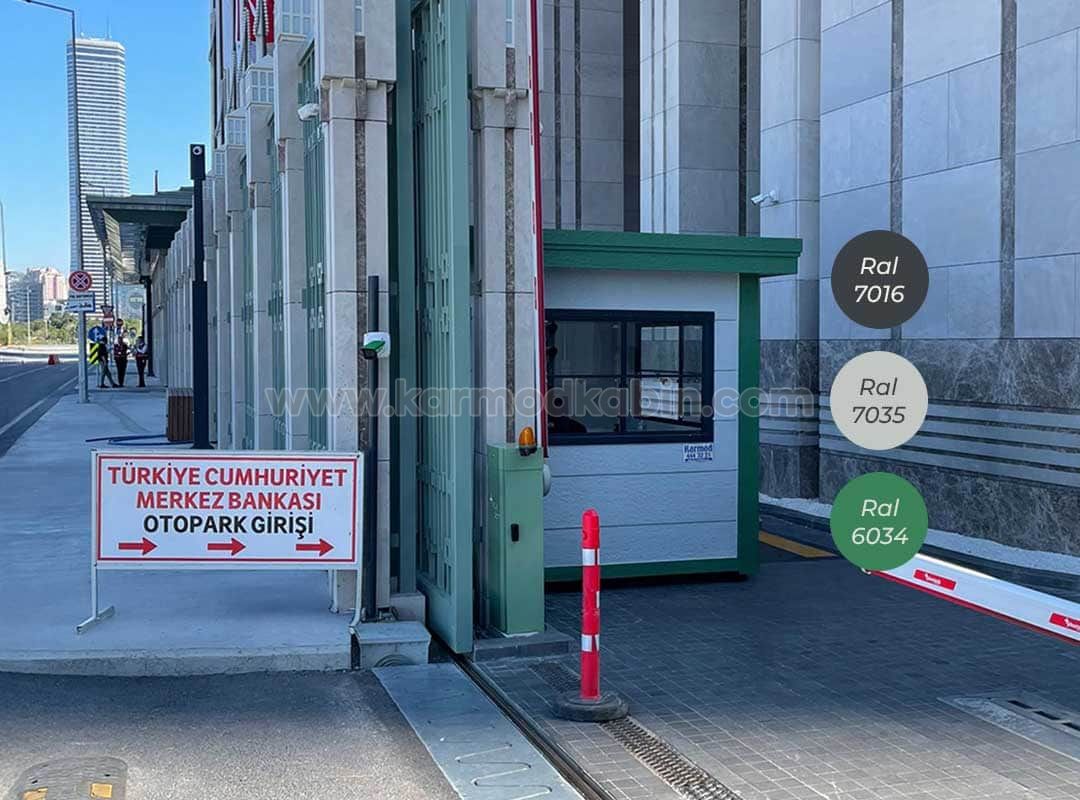

The painting process of cabins using RAL color codes is a precise and standardized method that ensures color accuracy, brand consistency, and long-lasting surface protection. In modern architectural and modular cabin production, especially for projects like MetroCity, aesthetics and corporate identity hold as much importance as structural quality. RAL codes provide a universal color-matching system used across Europe and worldwide, ensuring that the paint applied to every cabin perfectly aligns with the client’s chosen tone - whether it’s a deep matte gray, glossy white, or a custom corporate shade.

Using RAL-coded paints eliminates guesswork in color selection. Each code corresponds to a specific hue, saturation, and finish, which means that repainting, maintenance, or additional production in the future will look exactly the same. This level of precision is vital for organizations that require multiple cabins - such as retail kiosks, office cabins, or security booths - to reflect a unified brand image. In MetroCity projects, this uniformity reinforces professionalism and visual harmony across every installation.

The RAL color system provides an exact, reproducible method for defining and applying colors in industrial design. Each RAL tone corresponds to a unique formula that remains consistent across different paint batches, materials, and manufacturers. This eliminates discrepancies that often occur in large-scale production, ensuring that all cabins share the same visual identity. For companies like MetroCity, where multiple units are deployed across different locations, this color precision creates a strong sense of brand continuity and architectural symmetry.

On a deeper level, RAL-coded painting is a branding strategy as much as a technical standard. A brand’s signature color - whether a vibrant red, a deep gray, or a subtle beige - carries emotional and psychological significance. When applied precisely, it reinforces recognition, professionalism, and trust. Cabins painted with the correct RAL code don’t just serve functional purposes; they become visual extensions of the brand itself, turning architecture into identity.

Color consistency is one of the most overlooked yet powerful elements in corporate architecture. In large-scale projects like MetroCity, where multiple cabins serve different functions - such as retail kiosks, security stations, and information booths - maintaining a uniform color palette communicates organization and reliability. When customers or visitors see structures painted in consistent shades, they subconsciously associate the project with quality and professionalism.

Moreover, consistent RAL-coded painting simplifies long-term operations. Maintenance teams can easily match and touch up the exact color without trial and error. If new cabins are added years later, the same RAL code ensures perfect alignment with the existing units. This eliminates costly repainting jobs and keeps the overall environment visually cohesive, no matter how the project evolves.

The RAL-based painting process for cabins follows a systematic approach to ensure durability, adhesion, and visual perfection. Before any color is applied, the surface is meticulously prepared through cleaning, sanding, and priming to eliminate rust, grease, or dust particles. Once the surface is ready, layers of industrial-grade paint are sprayed evenly, allowing controlled drying times between each coat for maximum bonding strength. The result is a smooth, weather-resistant finish that resists fading, peeling, and corrosion even under harsh outdoor conditions.

The process typically includes:

This combination of mechanical precision and chemical quality control guarantees that every cabin painted with RAL standards maintains its vibrancy and professional appearance for years.

Proper surface preparation is the foundation of every professional cabin paint job. A poorly prepared surface can lead to peeling, uneven coverage, or premature wear - issues that no premium project can afford. The process involves removing contaminants such as oil, dust, and oxidation, followed by mechanical sanding or grit blasting to achieve ideal surface roughness.

Common preparation and priming steps include:

Each step contributes to a more durable and visually appealing result, ensuring that every RAL color layer adheres perfectly to the cabin’s surface.

The actual application of RAL paint is performed using high-precision spray systems to achieve even coverage and fine texture. Industrial-grade paints are applied in multiple coats to ensure depth and uniformity of color. Between coats, controlled drying intervals allow solvents to evaporate evenly, preventing blotching or uneven tones.

After painting, the curing stage is crucial. Cabins are placed in specialized ovens or temperature-controlled areas to accelerate hardening. This step enhances paint adhesion and surface resistance against scratches, chemicals, and UV rays. The final product is a cabin that not only looks premium but can withstand years of outdoor exposure without losing its shine or structural protection.

Before delivery, every painted cabin undergoes a detailed inspection to ensure full compliance with color standards and durability expectations. Technicians compare the finished surfaces to RAL reference charts using calibrated colorimeters. Any deviations are corrected through controlled touch-up or repainting procedures.

Beyond color precision, other parameters like gloss level, surface smoothness, and coating thickness are measured. This strict quality assurance process guarantees that each MetroCity cabin meets international coating standards and performs flawlessly under environmental stress.

Choosing RAL-coded paints offers multiple technical and operational advantages for cabin manufacturers and end users alike. These paints are formulated to deliver superior resistance to UV rays, humidity, and temperature variations - factors that often cause fading or corrosion in standard coatings.

Main advantages include:

These features make RAL-coded coatings a smart choice for companies that prioritize both visual excellence and sustainable construction.

The MetroCity project demonstrates how color precision can elevate the aesthetic and functional quality of modular architecture. Every cabin within the project was painted using RAL-coded systems to achieve uniformity across hundreds of individual units. This consistency strengthens the visual identity of the development and reflects meticulous project management.

From retail spaces to guard booths, each MetroCity cabin stands out as part of a coherent visual language. The controlled RAL painting process not only enhances appeal but also reinforces durability - ensuring that the cabins maintain their original appearance despite weather conditions, UV exposure, or heavy use.

Over time, even the most durable paint may require touch-ups due to physical wear or minor surface damage. The advantage of RAL coding is that it simplifies this process. Maintenance teams can easily identify the exact color code from previous records and reproduce the same shade without variation. This eliminates mismatched repairs and ensures that every cabin looks as seamless as the day it was installed.

In addition, repainting with RAL standards extends the overall service life of the cabin. When maintained correctly, RAL-painted surfaces can last for over a decade, providing both protection and aesthetic stability. Regular cleaning, surface inspections, and timely reapplications help preserve the brand’s professional look while reducing long-term maintenance costs.

We specialize in professional RAL-coded painting services for modular cabins, kiosks, and architectural steel structures. Our team combines industrial-grade materials, precision techniques, and brand-focused color management to deliver exceptional results for every project. Whether you need a single custom-painted cabin or an entire series for a corporate development like MetroCity Cabin, we ensure uniformity, durability, and unmatched visual impact.

Why work with us:

Contact us today to discuss your color and coating needs. Let us help you create cabins that reflect your brand’s strength, precision, and aesthetic excellence - with RAL-coded perfection built to last.