The cabin manufacturing industry is entering a new era, where robots are not just assisting workers but actually shaping and welding the cabin chassis themselves. Robotic technology, once limited to automotive or heavy machinery production, has now found its place in the world of prefabricated cabins and modular structures. This shift is redefining the meaning of precision, speed, and consistency in cabin manufacturing.

Automation in cabin chassis production eliminates the traditional barriers of manual assembly. With robotic arms capable of performing millimeter-perfect welds and cutting operations, production lines now operate around the clock with unmatched efficiency. Manufacturers adopting these systems can meet growing global demand for high-quality cabins while reducing error rates and overall production costs.

In recent years, automation has transformed the way cabins are built. The need for faster production, uniform quality, and scalable output has led companies to embrace robotic systems. Robots can perform tasks such as metal cutting, welding, drilling, painting, and material handling-tasks that used to require multiple human specialists.

Moreover, the integration of automation allows producers to customize cabin designs without compromising delivery times. From security booths to portable offices, robotic systems can easily adapt to different models, ensuring flexibility and consistency in every build.

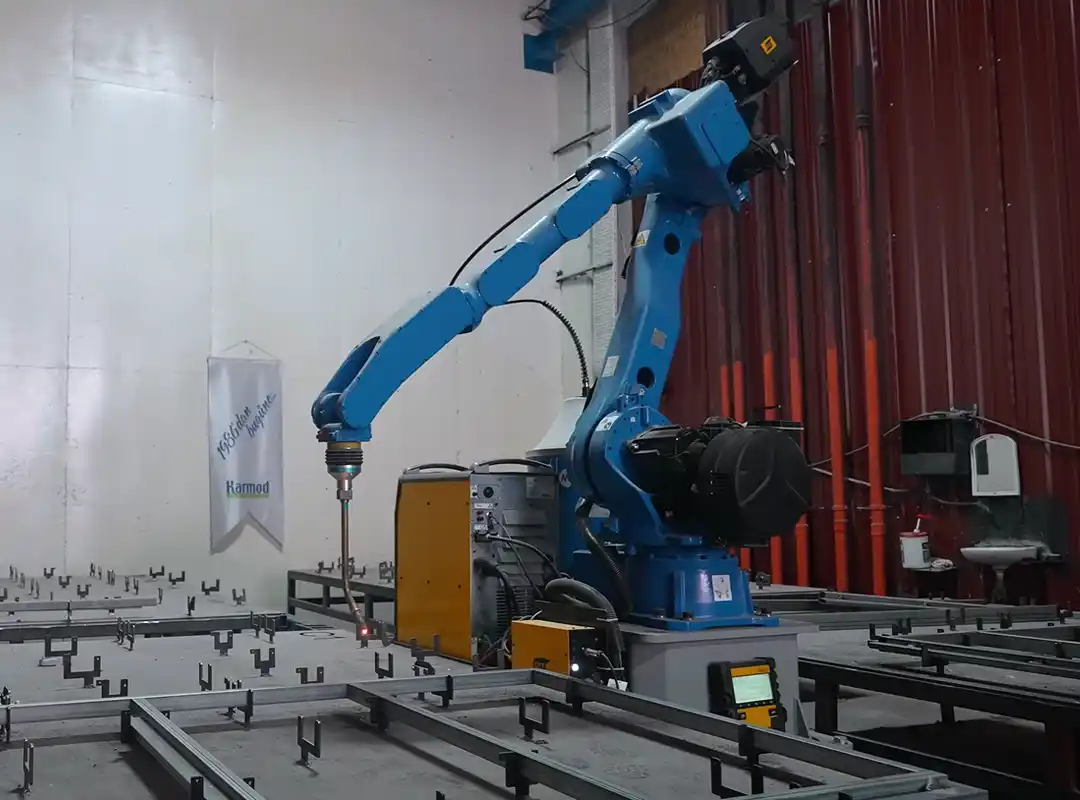

Robotic technology has dramatically transformed the cabin chassis production process. Where once human labor was the core of every stage-from cutting steel sheets to welding structural joints-today, robotic systems perform these operations with unparalleled accuracy and efficiency. Modern manufacturing plants now feature fully automated production lines equipped with robotic arms that can handle every step, from material feeding to final assembly.

The key advantage lies in consistency. Every chassis produced by a robotic system follows the same exact parameters, guaranteeing strength, alignment, and balance in every structure. This ensures that prefabricated and modular cabins maintain their integrity, especially when used in demanding environments like construction sites, security zones, or mobile offices.

Another major benefit is time efficiency. Robots can operate non-stop, delivering results that would typically take days within a matter of hours. They can also work in extreme conditions-such as high heat or confined spaces-where human performance would be limited.

Major Impacts of Robotics on Cabin Chassis Manufacturing

The success of robotic production in cabin chassis manufacturing lies in three defining strengths - precision, speed, and consistency. Each of these factors contributes to the superior performance of robotic systems compared to traditional manual production, making them an essential asset for modern cabin manufacturers.

When it comes to precision, robots can execute complex welding and cutting patterns with millimeter-level accuracy. This ensures that each chassis fits perfectly with other structural components, eliminating misalignment and reducing material waste. The result is a perfectly engineered base that enhances the durability and aesthetic appeal of every cabin, from portable offices to armored units.

Speed is another critical advantage. Robotic production lines can perform multiple tasks simultaneously - cutting, bending, welding, and assembling - without downtime. Unlike manual processes that rely on shift-based human labor, robots maintain continuous production, meeting high-volume demands effortlessly.

Consistency completes the equation. Each operation performed by a robot follows a pre-programmed path, ensuring that every single cabin chassis produced maintains the same level of quality and reliability. Whether you’re ordering ten or ten thousand units, robotic technology guarantees uniform strength and finish in each one.

Key Advantages in Robotic Precision Manufacturing

Modern cabin factories have evolved into smart production environments where cutting-edge robotic technologies take the lead in manufacturing every chassis component. These systems not only enhance accuracy but also enable a level of flexibility that traditional manual production methods simply cannot achieve.

One of the most significant advancements is the use of robotic welding arms. Equipped with sensors and AI-driven control systems, these robots perform uniform welds that strengthen the cabin chassis and prevent weak points over time. Similarly, CNC (Computer Numerical Control) cutting robots handle sheet metal with exact precision, ensuring that each piece perfectly matches the digital design files used in prefabricated cabin construction.

Common Robotic Technologies in Cabin Production

These technologies allow manufacturers to maintain high output levels without sacrificing quality, creating cabin chassis that are structurally strong, visually flawless, and ready for diverse applications-from security booths to residential modular homes.

The integration of robotic systems into cabin chassis production delivers powerful advantages that reshape the entire prefabricated housing industry. Manufacturers who invest in automation are not only achieving faster and more consistent results, but they’re also producing cabins that meet modern demands for quality, sustainability, and precision engineering.

One of the most important benefits is efficiency. Robots perform repetitive and complex tasks with incredible speed and accuracy, drastically reducing production time. This means customers receive their modular or prefabricated cabins in shorter lead times without compromising structural strength or visual appeal. The use of robotics also reduces material waste, supporting more eco-friendly and cost-effective manufacturing practices.

Another significant advantage is improved safety. Traditional cabin chassis construction involves welding, cutting, and lifting heavy materials - tasks that can expose workers to risks. Robotic systems take on these hazardous jobs, minimizing workplace accidents and creating a safer environment for human technicians who oversee quality and design aspects.

Key Benefits of Robotic Cabin Production

With these benefits combined, robotic cabin production is becoming the gold standard for modern prefab and modular construction - a step toward smarter, faster, and greener manufacturing.

While robotic systems have transformed cabin chassis production, human expertise remains an irreplaceable element of the process. The perfect balance between human creativity and robotic precision results in cabins that are not only structurally superior but also aesthetically refined and tailored to each client’s needs.

Robots bring consistency, endurance, and mechanical perfection - yet it is the human engineers, designers, and technicians who program, supervise, and refine these systems. Every automated welding line, cutting robot, or assembly arm depends on carefully calibrated instructions designed by skilled professionals. This collaboration ensures that technology serves human vision, rather than replacing it.

In cabin production, humans define the artistic and functional aspects - such as layout, ergonomics, and material combinations - while robots bring these visions to life with flawless execution. The outcome is a product that merges innovation with craftsmanship: a cabin chassis that reflects both technical mastery and human intelligence.

The Roles of Humans in Robotic Cabin Manufacturing

By combining human insight with robotic power, manufacturers achieve the best of both worlds - creativity, efficiency, and precision working in perfect harmony.

The future of cabin chassis production is being shaped by AI-driven robotics and smart manufacturing ecosystems. As artificial intelligence continues to evolve, robots are no longer limited to pre-programmed routines - they can now analyze data, make decisions, and self-optimize in real time. This advancement is redefining how modular and prefabricated cabins are designed, assembled, and delivered to global markets.

In modern factories, AI-powered robots use advanced sensors and machine-learning algorithms to monitor every weld, joint, and cut. When an error or deviation occurs, the system can automatically adjust its parameters to maintain precision. These intelligent systems don’t just execute; they learn from every production cycle, continually improving efficiency and reducing waste.

Another emerging trend is the integration of IoT (Internet of Things) technology. Smart sensors embedded throughout the production line allow managers to track every stage of the process remotely - from steel cutting to chassis finishing. Real-time data analytics helps predict maintenance needs, optimize energy consumption, and ensure seamless coordination between robotic systems.

Key Future Innovations to Watch

These innovations mark a new industrial revolution in cabin manufacturing - one where technology anticipates, adapts, and perfects itself with every movement, setting new global standards for efficiency and quality.

For customers, robotic cabin production represents more than a technological leap - it’s a guarantee of superior quality, durability, and precision in every structure they purchase. When robots take over the production of cabin chassis, every weld, cut, and joint is executed with identical accuracy. This consistency ensures that the final product not only looks refined but also performs reliably over many years of use, even in demanding environments such as construction sites, border checkpoints, or industrial zones.

Unlike traditional manual methods, robotic systems eliminate variability. Customers receive cabins that are structurally identical, meeting strict international standards for stability, insulation, and safety. Whether it’s a single security booth or a complex modular housing system, robotic production ensures the same level of perfection every time.

What Customers Gain from Robotic Cabin Manufacturing

For customers investing in prefabricated or modular cabins, robotic production means peace of mind - knowing their structure was built by machines programmed for perfection, supervised by experts dedicated to excellence.

Although robotic technology brings extraordinary precision and speed to cabin chassis production, challenges still exist in maintaining flawless performance across all systems. Like any advanced technology, robotic manufacturing depends heavily on accurate calibration, software reliability, and skilled human supervision to ensure consistent results.

One of the main challenges is system calibration. Even a slight misalignment in robotic welding arms or cutting sensors can lead to imperfections that compromise structural integrity. For this reason, most modern factories implement strict daily calibration routines and sensor checks. Another challenge is software synchronization-when different robotic systems operate simultaneously, timing and coordination must be exact to prevent delays or assembly errors.

To address these issues, manufacturers invest in advanced quality control protocols that combine robotic precision with human oversight. Automated inspection systems equipped with high-resolution cameras and AI algorithms analyze every chassis component before it leaves the production line. Meanwhile, experienced engineers review performance data, perform manual tests, and approve final products before delivery.

Essential Quality Control Measures in Robotic Cabin Production

Through this combination of automation and expert quality assurance, manufacturers maintain consistent excellence across all cabin chassis models - ensuring that each structure is built to perform reliably in any condition.

When you choose to buy from manufacturers that use robotic cabin production technology, you’re investing in unmatched quality, innovation, and long-term value. These factories operate with advanced automation systems that ensure every cabin chassis is built with flawless precision, delivering products that outperform traditionally manufactured alternatives.

By purchasing directly from a robotic-production manufacturer, you eliminate unnecessary middlemen, reduce costs, and gain direct access to custom-engineered solutions tailored to your needs. Whether you require a single security cabin, a modular office, or a full-scale prefabricated living complex, robotic production ensures the highest standards of durability, design, and accuracy - delivered faster and more efficiently.

Why Choose Robotic Cabin Production Manufacturers?

Modern buyers value reliability, sustainability, and innovation - and robotic cabin manufacturing delivers all three. When you partner with us, you gain more than just a product; you secure a structure built for the future, shaped by technology, and perfected through expertise.

Get in touch today to explore our robotic-produced modular and prefabricated cabin models - engineered for precision, designed for performance, and crafted to last.